Tag-Connect cables provide a simple, secure way to connect debuggers, programmers and test equipment to your PCBs while saving space and cost on every board.

Our patented connectors connect directly to a tiny footprint of pads and holes in your PCB – No mating connector or component is required, the PCB itself is the mating connector. The footprint can be about the size of an 0805 resistor, and being just a footprint (no special PCB finish required), it also has no height which means Tag-Connect footprints can often be placed on the back of a PCB or somewhere where physical space is otherwise constrained.

Tag-Connect thus eliminates the need for a programming / test header or JTAG connector on your PCB, saving you both the cost of the connector and potentially a most of PCB real-estate traditionally required.

Our connectors use tried and tested pogo-pins (spring-pins) to make a reliable electrical connection – a connection you can trust – for as long as is required.

When you’re done, the Tag-Connector is disconnected and is suitable for repeated use just like a conventional connector, in fact the spring-pins in our cycle testing easily last for well over 100,000 operations. Typically, it’s the ribbon cable that is the part that fails first.

Traditional Tag-Connect cables are currently available in two versions: ‘Legged’ and “No Legs”. Both have a Tag-Connect connector on one end, and a traditional connector on the other. We have solutions for just about every family of popular MCU, DSP, PSoC and programmable devices. We also have an exciting new family called Edge-Connect™ that save

Tag-Connect footprints are found everywhere, there’s very likely several products in your home and office and garage that use them such as coffee machines, appliances, garage door openers, medical devices, blenders, in fact if it uses an MCU or an FPGA, there’s a fair chance it uses Tag-Connect. Our footprints are frequently found on popular eval boards from big-name semiconductor companies such as TI (launchpads), Microchip (Atmel), Renesas, Nordic, Maxim, Analog, Silicon Labs, Intel, etc.

In fact, many industry standard Programmers / Debuggers now themselves use Tag-Connect including Segger J-Link, P&E (PE Micro Multilink), ARM (Keil) ULINKplus etc.

We offer Tag-Connect solutions for most popular target devices and programmers. To learn more about which type of Tag-Connector may best be suited to your needs, see Which Tag-Connect?

Tag-Connect Legged connectors looks like this:

The legged version ‘Snaps’ into this custom designed footprint. To insert, you position the connector and squeeze the two sides and push to snap it into place. To remove, squeeze the two sides again and it pops right out.

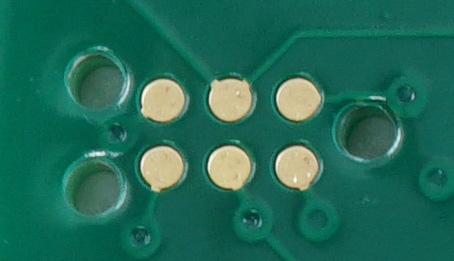

Tag-Connect No Legs (TC2030-MCP-NL) looks like this:

The Tag-Connect “No Legs” version saves even more space than the ‘Legged’ version… which has made it very popular for use on tiny PCBs such as Bluetooth Beacons, Implantable medical devices, and anywhere where space is premium.

It connects into a tiny footprint – hardly bigger than a surface mounted resistor…

Note that it can also be used with the Legged footprint.

It is hand-held in position – ideal for production programming. Or you can use the one of our retaining solutions such as a CLIP board to maintain a hands free connection whilst. It’s also frequently used in custom made fixtures or Bed-of-Nails type applications for volume manufacturing.